What role does precision forging play in missile segment manufacturing?

Optimized Grain Alignment for Structural Strength

Precision forging ensures that grain flow aligns with the natural stress paths of missile segments, resulting in components with superior load-bearing capabilities. Alloys such as Inconel 718 and Rene 77 benefit significantly from superalloy precision forging, which enhances their fatigue resistance and tensile strength—critical for high-speed missile operation.

Enhanced Fatigue and Impact Resistance

Missile segments experience continuous vibration, shock loads, and pressure fluctuations. Forged microstructures are denser and more uniform than those from traditional casting, reducing the risk of crack initiation. Post-forging treatments such as superalloy heat treatment further stabilize phase distribution and promote strong γ′ precipitation for high-temperature durability.

Weight Reduction and Structural Efficiency

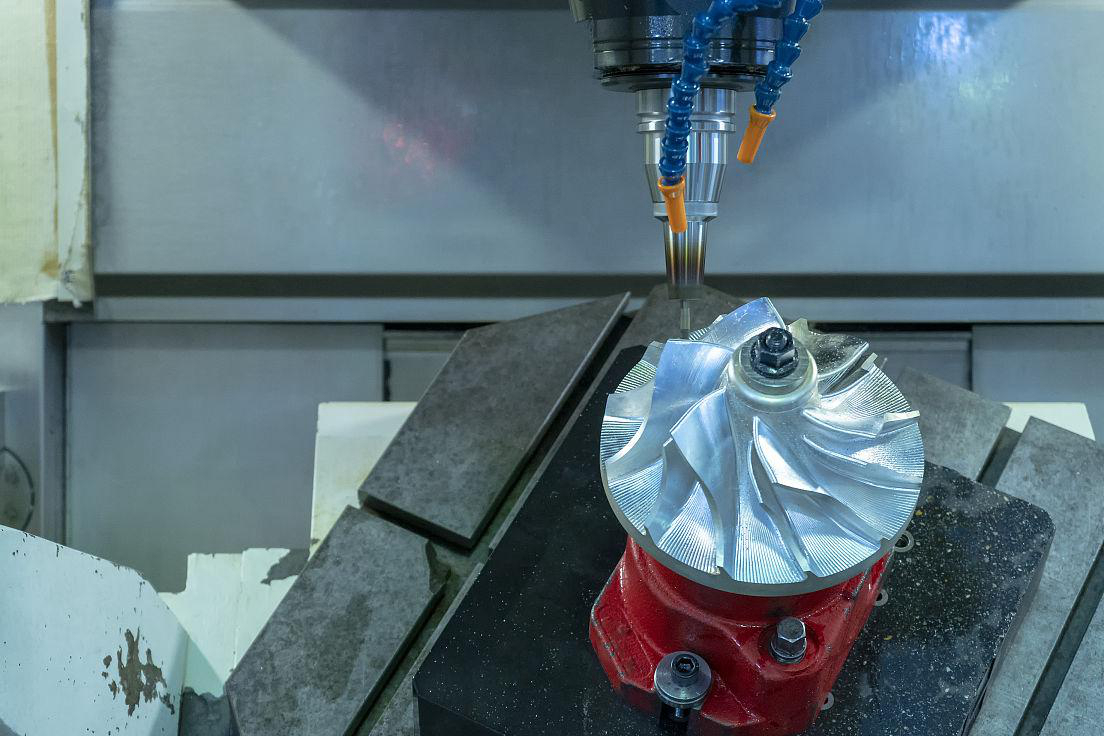

Precision forging supports the integration of lightweight design strategies while preserving mechanical strength. This allows engineers to optimize missile maneuverability and fuel efficiency. Critical components may be forged into near-net shapes to reduce secondary machining, later refined with superalloy cnc machining for exact dimensional control.

Combination with Multistage Manufacturing Processes

Precision forging is frequently coupled with vacuum investment casting and superalloy 3d printing to produce complex missile structures. Near-net preforms are then forged to improve density, followed by hot isostatic pressing (HIP) to enhance fatigue resistance. This workflow ensures manufacturing flexibility while maintaining aerospace-grade reliability.

Application in Defense and High-Reliability Systems

Precision forging provides process traceability and structural reliability—key requirements in the military and defense and aerospace and aviation sectors. Missile segments produced through forging exhibit improved operational stability during rapid acceleration, pressure changes, and extreme temperature fluctuations during flight.