What quality control tests are essential for ensuring the integrity of rough-forged components?

Comprehensive Non-Destructive Examination (NDE)

Ensuring the integrity of rough-forged components begins with rigorous non-destructive testing. Material Testing and analysis begin with ultrasonic testing (UT), which is crucial for detecting internal flaws such as voids, inclusions, or cracks within the bulk material. This is complemented by surface examination methods, such as liquid penetrant testing (PT) or magnetic particle testing (MT), to identify surface-breaking discontinuities, like seams or laps, that may have formed during the forging process. For critical components destined for aerospace or nuclear applications, these tests are mandatory to validate the internal soundness of the forging before it proceeds to costly machining.

Verification of Metallurgical and Microstructural Properties

The quality of a forging is defined by its microstructure. Metallographic analysis is performed on witness coupons or sections from the forging to verify grain size, flow lines, and the absence of detrimental phases. This confirms that the forging and subsequent heat treatment have produced the intended microstructure for optimal mechanical properties. Chemical analysis via spectroscopy is also conducted to ensure the material composition conforms to the specified grade, a critical step for maintaining corrosion resistance and high-temperature performance in alloys like Inconel 718.

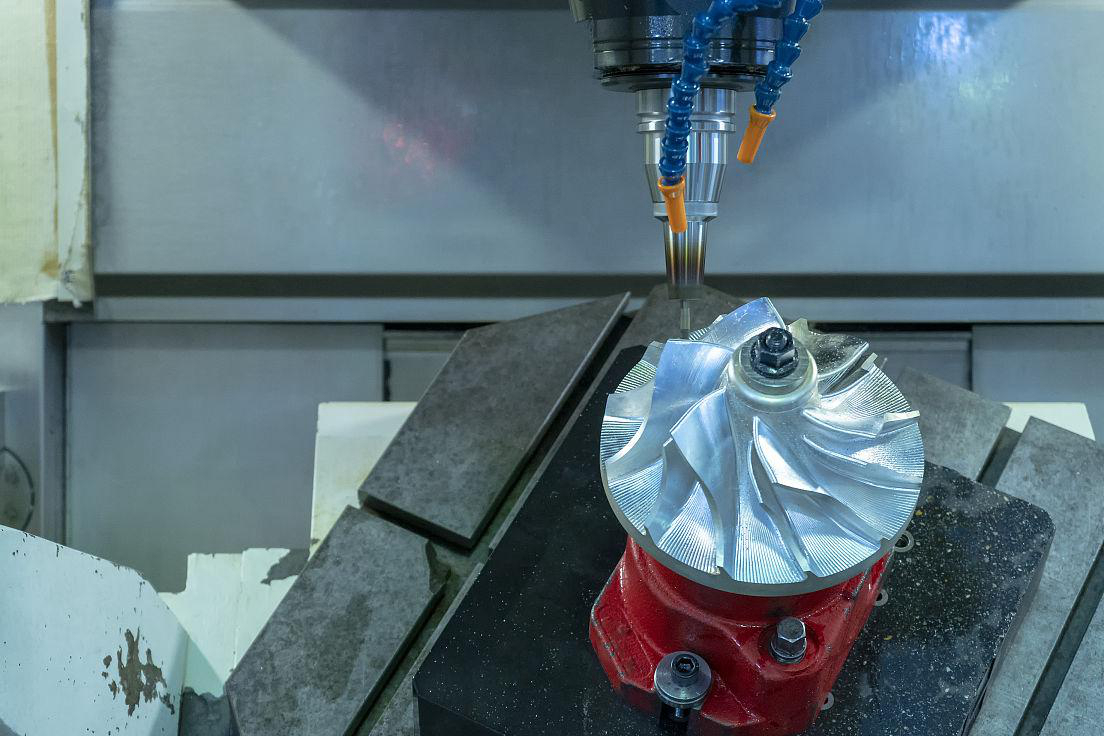

Dimensional and Geometric Inspection

While rough forgings are near-net-shape, they must still conform to specific dimensional envelopes to ensure sufficient stock for final CNC machining. Precision metrology tools, including laser scanners and coordinate measuring machines (CMMs), are used to verify critical dimensions, wall thicknesses, and overall geometry against forging drawings. This step is crucial for preventing machining issues and ensuring the part can be finished to its final tolerances without compromising design integrity.

Mechanical Properties Verification

Direct verification of mechanical properties is fundamental. Tensile, impact (Charpy), and hardness tests are performed on coupons extracted from the forging or from representative test bars processed alongside the component. This data validates that the forging meets the required strength, ductility, and toughness specifications. For parts that will undergo further enhancement like Hot Isostatic Pressing (HIP), baseline mechanical tests provide a critical benchmark for comparing post-process performance improvements.