How does precision forging improve the strength of superalloy parts?

Grain Refinement and Microstructure Optimization

Precision forging provides superior control over grain flow and distribution, significantly enhancing the mechanical strength of superalloy components. Through optimized deformation and controlled cooling, grain boundaries are aligned with load paths, reducing weak points and improving resistance to crack initiation. Alloys such as Rene 65 and Inconel 718 achieve significantly enhanced creep strength after forging, especially when followed by tailored heat treatments.

Directional Strength and Fatigue Resistance

Unlike cast structures, forged superalloy parts exhibit a directional grain orientation, which allows for better resistance to cyclic loading and thermal fatigue. When combined with superalloy heat treatment, forged components develop stable microstructures with high γ′ precipitation, thereby enhancing their high-temperature strength. This is particularly critical in rotating components and turbine assemblies operating under extreme thermal cycles.

Reduction of Defects and Porosity

Precision forging substantially reduces casting-related defects, including porosity, segregation, and shrinkage cavities. This elevates the overall reliability of safety-critical components. Forged parts may still undergo hot isostatic pressing (HIP) to ensure complete densification and remove internal voids, providing further fatigue life extension.

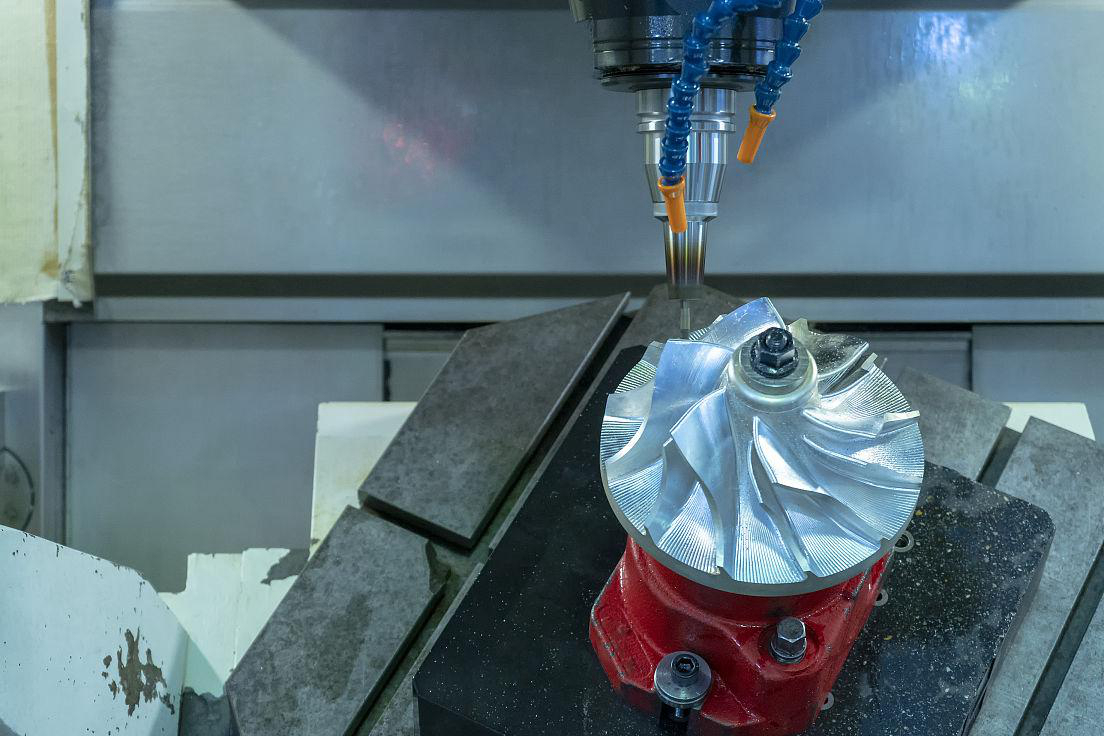

Integration with Advanced Manufacturing Processes

Precision forging is often combined with semi-finished processes such as vacuum investment casting or near-net-shape superalloy 3d printing to form an optimized process chain. The forged billet is then finished using superalloy CNC machining to achieve tighter tolerances for demanding applications in aerospace and power generation sectors.