Which superalloys are mainly used for containment system accessories?

Performance Requirements of Containment Systems

Containment system accessories must withstand high pressure, radiation exposure, chemical attack, and temperature fluctuations over extended periods of service. These components often provide secondary safety barriers, meaning that material selection must ensure dimensional stability, corrosion resistance, and structural integrity without compromising performance. Superalloys are preferred because they retain mechanical strength and resist stress corrosion cracking in harsh nuclear or chemical environments.

Commonly Used Superalloys for Containment Accessories

Nickel-based alloys dominate containment system applications due to their strong thermal stability and resistance to irradiation. Grades such as Inconel 690 and high-strength Inconel 718 are widely used for pressure-retaining housings and sealing components. In highly corrosive zones, molybdenum-enhanced alloys such as Hastelloy C-276 offer exceptional resistance to chloride-induced corrosion and chemical attack.

For wear-intensive interfaces exposed to abrasive working fluids, cobalt-based materials such as Stellite 6B are ideal due to their high hardness and resistance to erosion. These properties help maintain sealing ability and prevent galling in actuator and valve interfaces.

Manufacturing and Microstructure Optimization

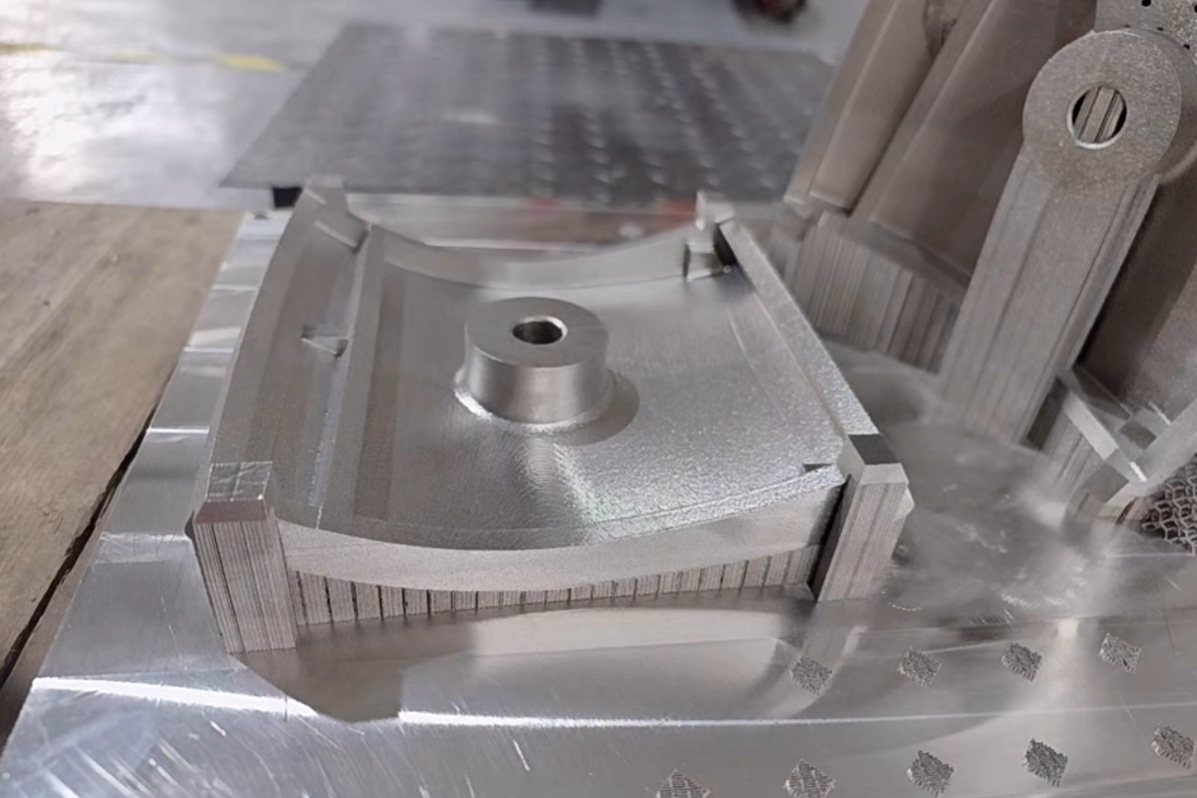

To achieve structural uniformity and reduce flaw initiation sites, containment system parts are often produced using vacuum investment casting or refined grain techniques such as equiaxed crystal casting. For directional strength along stress paths, precision forging is applied to enhance fatigue resistance.

Critical structural accessories undergo post-treatment using processes such as hot isostatic pressing (HIP) to remove internal voids and increase density. Final assembly precision is achieved through CNC machining, ensuring sealing reliability in safety-critical housings and connectors.

Industry Applications

Containment system accessories made from superalloys are used in nuclear containment, chemical reactors, and high-pressure safety chamber applications. Their ability to maintain structural integrity under irradiation, pressure, and corrosion significantly enhances system reliability and safety across decades of operation.