Marine Turbine Blade Superalloy Parts Foundry

Introduction to Marine Turbine Blade Manufacturing

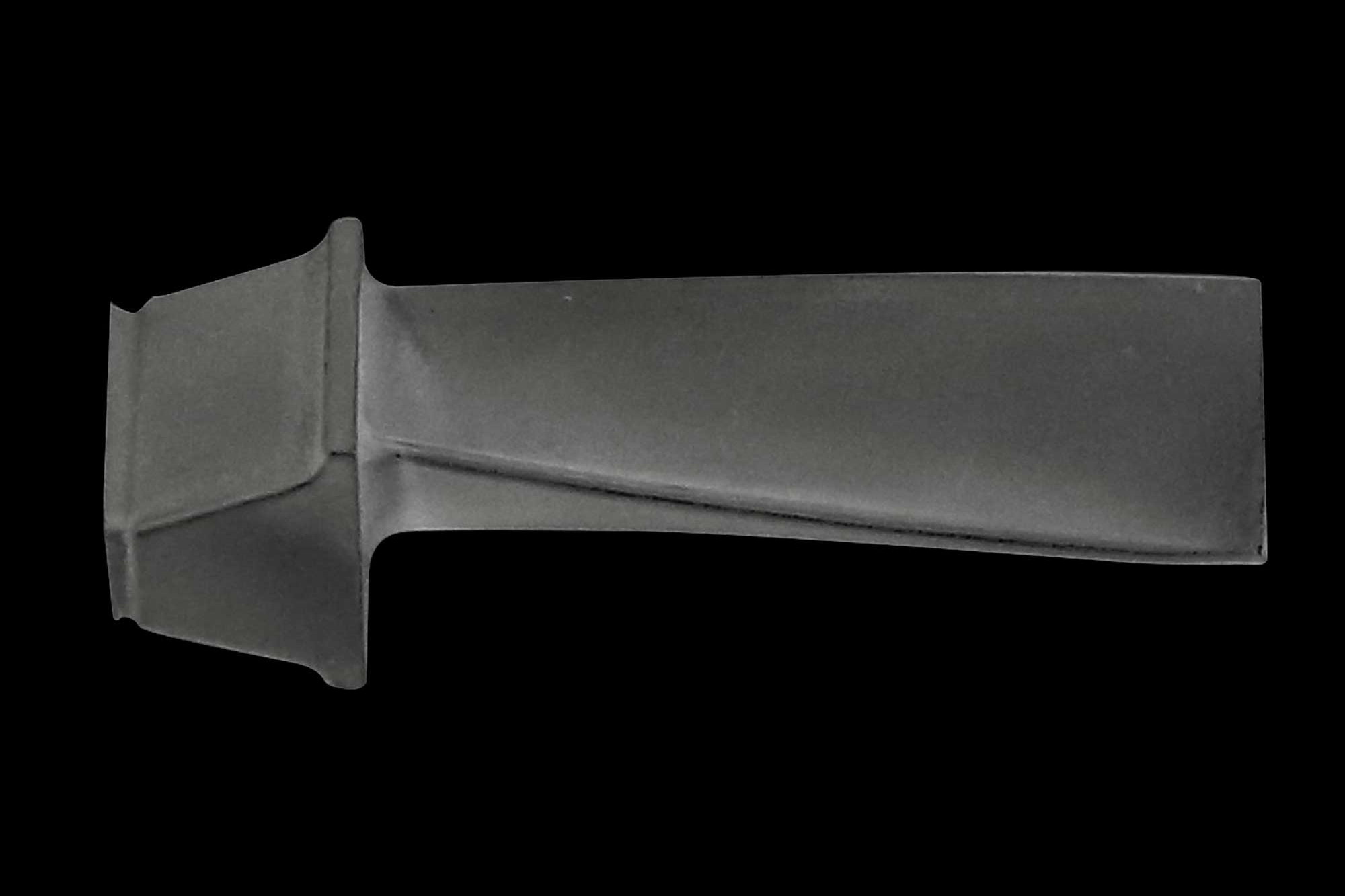

Marine turbine blades require superior corrosion resistance, mechanical strength, and high-temperature stability to perform reliably in harsh maritime conditions. At Neway AeroTech, a specialized superalloy foundry, we manufacture precision marine turbine blades tailored for critical marine propulsion systems. Employing advanced techniques like vacuum investment casting, we ensure exceptional dimensional accuracy, durability, and long-term operational efficiency.

Our extensive industry experience and advanced manufacturing capabilities position us as leaders in marine turbine blade production.

Key Challenges in Marine Turbine Blade Manufacturing

Marine turbine blades face challenging operational demands:

Corrosion Resistance: Must withstand continuous exposure to harsh saline environments.

Mechanical Strength: Require high tensile strengths (>1000 MPa) to withstand rigorous marine propulsion stresses.

Fatigue and Creep Stability: Blades must maintain structural integrity under continuous load and elevated temperatures (~1000°C).

Precision Tolerances: Dimensional precision must reach ±0.10 mm, with surface finishes down to Ra 1.6 µm.

Marine Blade Manufacturing Processes Explained

Vacuum Investment Casting

Precise wax patterns are created to replicate complex geometries.

Ceramic molds form around patterns; wax removal occurs at controlled temperatures (~180°C).

Vacuum casting at pressures <0.01 Pa guarantees purity and material consistency.

Controlled cooling rates (20–35°C/hour) minimize internal stresses and structural defects.

Directional and Single Crystal Solidification

Thermal gradients (20–50°C/cm) enable grain structure control.

Single-crystal techniques remove grain boundaries, significantly improving creep and fatigue resistance.

Controlled cooling (20–35°C/hour) reduces defects, enhancing blade integrity.

Comparison of Marine Blade Manufacturing Techniques

Technique | Dimensional Accuracy | Surface Finish | Efficiency | Geometry Complexity |

|---|---|---|---|---|

Vacuum Investment Casting | ±0.15 mm | Ra 3.2–6.3 µm | Moderate | High |

Single Crystal Casting | ±0.20 mm | Ra 6.3–12.5 µm | Moderate | High |

CNC Machining | ±0.01 mm | Ra 0.8–3.2 µm | Moderate | Moderate |

SLM 3D Printing | ±0.05 mm | Ra 6.3–12.5 µm | High | Very High |

Process Selection Strategy for Marine Blades

Vacuum Investment Casting: Optimal for intricate blade geometries, achieving ±0.15 mm tolerances with exceptional metallurgical integrity.

Single Crystal Casting: Ideal for blades demanding peak creep resistance at ±0.20 mm accuracy in high-temperature applications.

CNC Machining: Best suited for precise surface finishing and achieving strict dimensional tolerances (~±0.01 mm).

SLM 3D Printing: Effective for rapid prototyping and creating internal cooling channels, maintaining ±0.05 mm dimensional accuracy.

Superalloy Material Performance Matrix for Marine Turbine Blades

Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Max Temp (°C) | Corrosion Resistance | Application |

|---|---|---|---|---|---|

880 | 480 | 980 | Excellent | General marine blades | |

750 | 360 | 1038 | Exceptional | Corrosion-intensive blades | |

1050 | 585 | 815 | Excellent | High-strength marine blades | |

1170 | 850 | 1000 | Superior | High-temp propulsion blades | |

1300 | 1000 | 1150 | Exceptional | Single-crystal blades | |

860 | 700 | 850 | Excellent | High-wear turbine blades |

Material Selection Guidelines

Inconel 625: Chosen for excellent marine corrosion resistance and strength (880 MPa tensile) at temperatures up to 980°C.

Hastelloy C-276: Recommended for highly corrosive marine environments, maintaining performance up to 1038°C.

Nimonic 80A: Preferred for high-strength marine blades with exceptional tensile performance (1050 MPa) at moderate temperatures (~815°C).

Rene 41: Selected for superior strength (1170 MPa) and durability under sustained high-temperature conditions (~1000°C).

CMSX-4: Optimal choice for single-crystal blades requiring ultimate creep resistance at temperatures up to 1150°C.

Stellite 6: Best for marine blades facing severe wear and abrasion, suitable for temperatures up to 850°C.

Key Post-processing Technologies

Hot Isostatic Pressing (HIP): Removes internal porosity, enhancing blade integrity at ~1200°C, 150 MPa pressure.

Thermal Barrier Coating (TBC): Lowers surface temperatures (~200°C), significantly extending blade lifespan.

Electrical Discharge Machining (EDM): Enables intricate internal structures and precise dimensional control (±0.005 mm tolerance).

Heat Treatment: Optimizes microstructure to improve mechanical properties, corrosion resistance, and fatigue performance.

Marine Industry Case Study: Precision Blade Production

Neway AeroTech recently delivered vacuum investment-cast Inconel 625 blades to a leading marine propulsion OEM. Utilizing HIP and TBC, we achieved precise dimensional tolerances (±0.15 mm), outstanding corrosion resistance, and significantly extended operational life, surpassing typical industry expectations.

Our advanced casting technology and alloy expertise firmly position us as a trusted marine turbine blade manufacturer.

FAQs

What is your standard lead time for marine turbine blade orders?

Can your foundry handle small-batch or prototype marine blade manufacturing?

Which quality standards and marine certifications do your turbine blades comply with?

What post-processing methods do you recommend for maximizing blade lifespan in marine conditions?

Do you offer technical support for alloy selection and blade design optimization for marine applications?