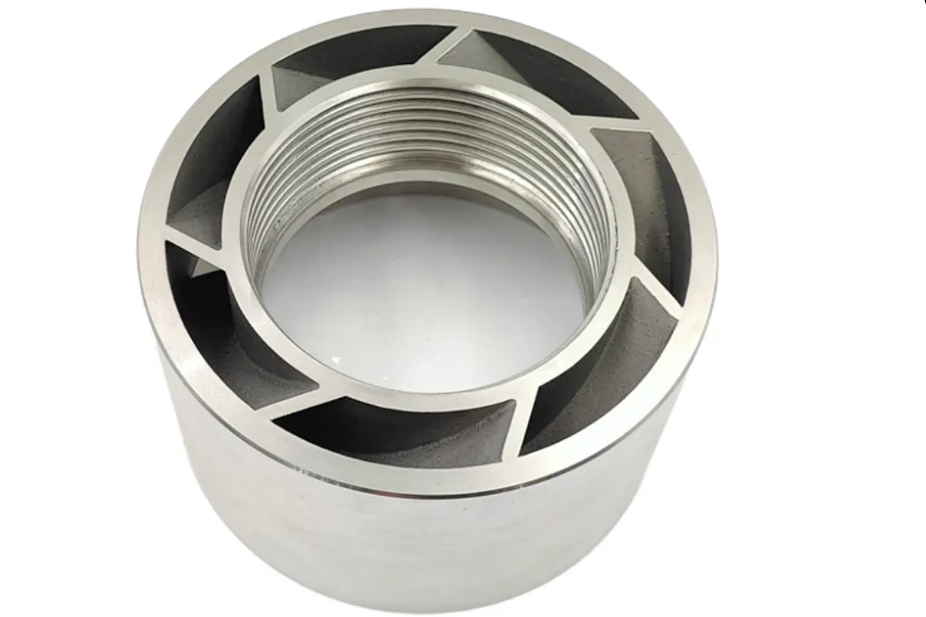

Hastelloy Alloy Nuclear Parts Powder Metallurgy Turbine Disc Company

Introduction to Hastelloy Turbine Discs for Nuclear Applications

Hastelloy alloys are indispensable in nuclear energy systems, offering unmatched corrosion resistance, thermal stability, and mechanical strength under radiation and extreme temperatures. As a leading manufacturer, Neway AeroTech produces custom Hastelloy alloy parts using powder metallurgy turbine disc technology, ensuring enhanced material performance for critical nuclear applications.

We specialize in precision-engineered Hastelloy turbine discs tailored for nuclear turbines and reactor components. Our advanced powder metallurgy solutions offer microstructural uniformity, isotropic properties, and long-term operational stability, making them ideal for high-integrity nuclear environments.

Manufacturing Challenges of Hastelloy Nuclear Turbine Discs

Producing turbine discs for nuclear use presents unique challenges requiring strict engineering control:

Radiation Stability: Materials must retain mechanical properties under neutron bombardment and gamma radiation.

Corrosion Resistance: Components must endure aggressive environments, including borated water and high-pressure steam.

Dimensional Precision: High-precision disc profiles are essential for dynamic balance and thermal efficiency.

Grain Structure Control: Fine, uniform grain size is required to enhance fatigue life and creep resistance at 750–950°C.

Powder Metallurgy Process for Hastelloy Turbine Disc Manufacturing

Gas Atomization & Powder Selection

High-purity Hastelloy alloy powders (particle size 15–45 µm) produced via inert gas atomization.

Chemical homogeneity and low oxygen content ensure excellent base powder integrity.

Cold Isostatic Pressing (CIP)

Metal powder is compacted into preform shape under pressures of 200–400 MPa using rubber molds.

Uniform green density ensures consistent sintering behavior.

Vacuum Sintering & Hot Isostatic Pressing (HIP)

Sintered under vacuum (~10⁻³ Pa) at 1150–1250°C to achieve metallurgical bonding.

HIP treatment at ~1200°C and 100–150 MPa consolidates density to >99.9%, eliminating residual porosity.

Precision Machining & Heat Treatment

Finish machining to ±0.01 mm tolerances.

Final heat treatment optimizes grain structure and creep properties for long-term high-temperature stability.

Comparison of Hastelloy Disc Manufacturing Methods

Method | Density (%) | Grain Control | Mechanical Strength | Defect Rate | Best Use Case |

|---|---|---|---|---|---|

Powder Metallurgy (HIP) | >99.9 | Excellent | Very High | Minimal | Nuclear turbine discs |

Forging | 96–98 | Good | High | Moderate | Structural nuclear components |

Casting | 92–95 | Poor | Moderate | High | Non-critical parts |

Hastelloy Grades for Nuclear Turbine Disc Applications

Material | Yield Strength (MPa) | Max Temp (°C) | Corrosion Resistance | Radiation Resistance | Application |

|---|---|---|---|---|---|

385 | 1200 | Excellent | Good | Hot section turbine discs | |

420 | 1050 | Outstanding | Superior | Molten salt reactor turbine interfaces | |

370 | 1100 | Superior | Good | Steam generator rotor sections | |

380 | 1100 | Excellent | Excellent | Reactor-grade rotating parts |

Alloy Selection Strategy for Nuclear Turbine Discs

Hastelloy X: Used for turbine discs exposed to combustion or high radiation, maintaining tensile properties at 1200°C.

Hastelloy N: Ideal for molten salt reactor applications, with superior resistance to fluoride salt corrosion and neutron irradiation.

Hastelloy C-276: Best for discs in corrosive steam environments, combining corrosion protection with moderate creep strength.

Hastelloy S: Optimal where strength and oxidation resistance must be preserved under long-duration high-temperature exposure.

Post-Processing Techniques for Powder Metallurgy Discs

Hot Isostatic Pressing (HIP): Critical to densify sintered parts, remove porosity, and improve mechanical properties to forge-like levels.

Heat Treatment: Refines microstructure and enhances creep and fatigue resistance for continuous operation above 950°C.

CNC Machining: Achieves tight tolerances (±0.01 mm) and precision balancing critical for rotating turbine components.

Material Testing and Analysis: Ensures ISO/ASME compliance through tensile, creep, and metallography inspections.

Industry Case Study: Hastelloy N Turbine Disc for Nuclear Molten Salt Reactor

Neway AeroTech engineered a Hastelloy N powder metallurgy turbine disc for a next-generation molten salt reactor turbine. The disc was manufactured via HIP using ultra-fine spherical powder and underwent heat treatment to stabilize grain boundaries for prolonged high-temperature exposure.

The final product achieved over 99.9% density, creep resistance exceeding 150 MPa at 950°C, and passed radiographic, ultrasonic, and SEM testing. The disc demonstrated zero deformation during accelerated thermal cycling and improved lifespan by 60% over forged equivalents.

FAQs on Hastelloy Powder Metallurgy Discs for Nuclear Use

What are the mechanical advantages of powder metallurgy over forging for Hastelloy turbine discs?

Which Hastelloy grades are recommended for high-radiation nuclear environments?

What testing standards do your nuclear-grade turbine discs meet?

Can you provide dimensional accuracy and balancing for rotating turbine components?

What is the typical production lead time for Hastelloy powder metallurgy turbine discs?