Supersonic Thermal Barrier Coating for Shafts

Introduction

Shafts operating in high-temperature environments—such as turbine spindles, exhaust drive shafts, and rotor shafts—are exposed to thermal fatigue, oxidation, and hot gas corrosion. To maintain dimensional stability and prevent premature failure, these components require advanced surface protection. Our supersonic thermal barrier coating (TBC) solution, applied via High-Velocity Oxy-Fuel (HVOF) or supersonic plasma spray, delivers durable, thermally resistant coatings that enhance the longevity and reliability of critical rotating shafts in aerospace and industrial gas turbine applications.

We specialize in TBC systems engineered for shaft components in propulsion, energy, and thermal process systems, where resistance to heat, oxidation, and mechanical stress is essential.

Why Shafts Need Supersonic TBC

Shafts used in hot-section machinery experience:

High radiant and convective heat exposure (typically 800–1100°C)

Thermal cycling during engine startup and shutdown

Oxidation and hot corrosion from ambient gas mixtures

Surface fatigue from high-speed rotation under stress

Supersonic TBC provides a barrier that significantly reduces shaft surface temperature, limits oxidation, and improves fatigue performance by mitigating thermal expansion mismatches between the substrate and surrounding components.

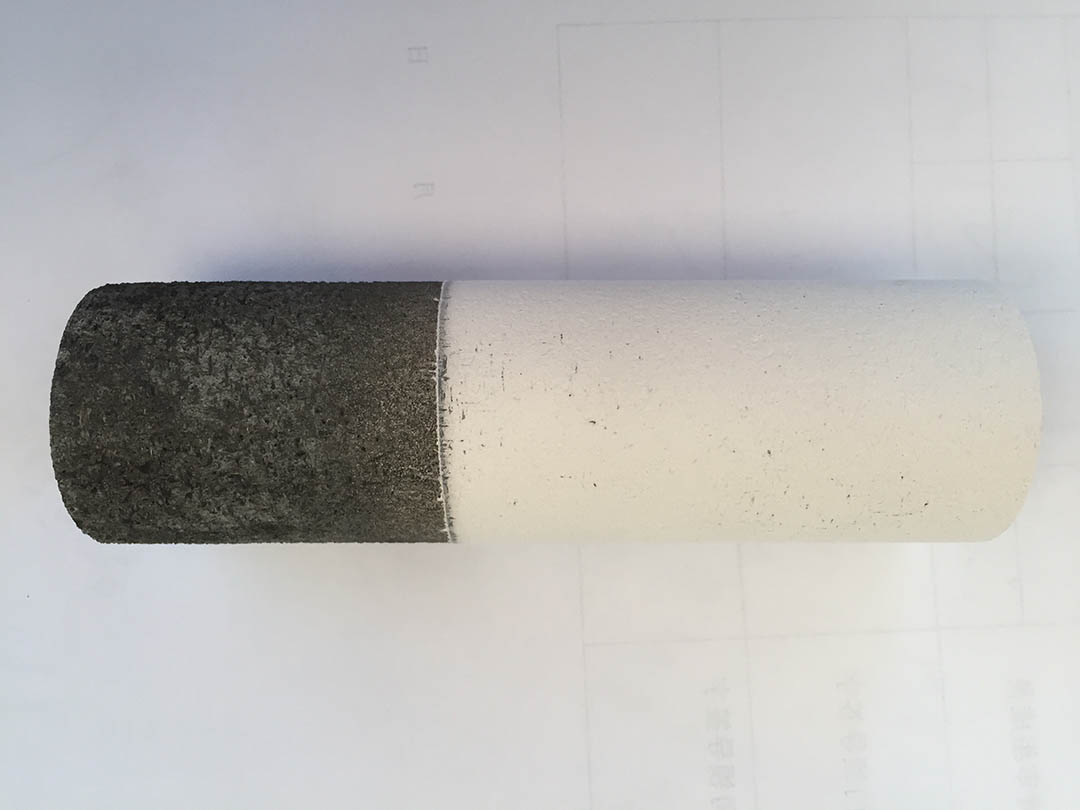

Coating Structure

Layer | Material | Function |

|---|---|---|

Bond Coat | MCrAlY or NiCrAlY via HVOF | Enhances adhesion and provides oxidation/corrosion protection |

Top Coat | 7–8 wt% Yttria-Stabilized Zirconia (YSZ) | Provides thermal insulation and strain compliance |

Coating thickness typically ranges from 200–350 μm, optimized per shaft application and operating conditions.

Applicable Shaft Materials

We coat a variety of heat-resistant and high-strength shaft substrates, including:

Inconel 718 / IN738LC – High-temperature alloy shafts used in turbines and thermal systems

Mar-M 247, Rene 80, Rene N5 – Nickel superalloy shafts in jet engine rotor applications

Hastelloy X, Haynes 230 – Shafts in combustion systems and heat exchangers

High-Speed Tool Steel (H13, M42) – Forged steel shafts in industrial rotating assemblies

Each material requires specific grit blasting, preheating, and interlayer preparation for optimal adhesion and thermal performance.

Supersonic TBC Application Process

1. Surface Preparation

Grit blasting with alumina media to achieve Ra 3–5 μm

Preheating to reduce thermal shock during deposition

Masking of critical surfaces (bearings, threads, seats)

2. Bond Coat Deposition

Applied via HVOF spray for high-density, low-porosity bond layer

NiCrAlY or CoNiCrAlY chosen based on oxidation and corrosion conditions

3. YSZ Top Coat Application

Deposited using supersonic plasma spray (APS at high velocity)

Controlled porosity (~10–15%) to relieve thermal stress and provide insulation

4. Post-Coating Conditioning

Optional sealing or densification to improve spallation resistance

Dimensional grinding or polishing to meet shaft fit tolerances

Performance Advantages

Feature | Benefit |

|---|---|

Thermal Insulation | Reduces surface temperature by up to 200°C |

Oxidation Resistance | Protects shaft from thermal scaling and gas-phase corrosion |

Fatigue Life Extension | Reduces thermal expansion stress and cracking under cyclic loading |

Improved Reliability | Maintains dimensional and mechanical integrity during long service life |

Lower Maintenance Frequency | Reduces need for premature shaft replacement or refurbishment |

Testing and Quality Validation

We follow aerospace and industrial specifications for shaft coating validation:

Coating Thickness (±10 μm)

Adhesion Strength (ASTM C633) ≥ 30 MPa

Thermal Shock Testing (up to 1000 cycles @ 1000°C)

SEM and Microstructure Analysis

Bond coat oxidation layer evaluation

Application Examples

GE LM2500 Power Turbine Shafts: YSZ TBC applied for naval and industrial turbine rotor shaft insulation

Rolls-Royce AE 2100 Compressor Shafts: Supersonic coating used for oxidation control in high-speed shaft assemblies

Aero-Derivative Generator Drive Shafts: Plasma TBC used in generator interface shafts exposed to hot exhaust zones

Refinery Combustor Shafts: HVOF + ceramic coating applied to rotating combustion shafts in oil and gas processing units

FAQs

What’s the maximum temperature supersonic TBC can handle for shaft applications?

Can thermal barrier coatings be reapplied during shaft refurbishment?

How thick should the ceramic layer be on turbine shafts?

What’s the difference between HVOF and APS coatings for rotating components?

How do you ensure uniform coating thickness around complex shaft profiles?