AlSi10Mg

Material Introduction

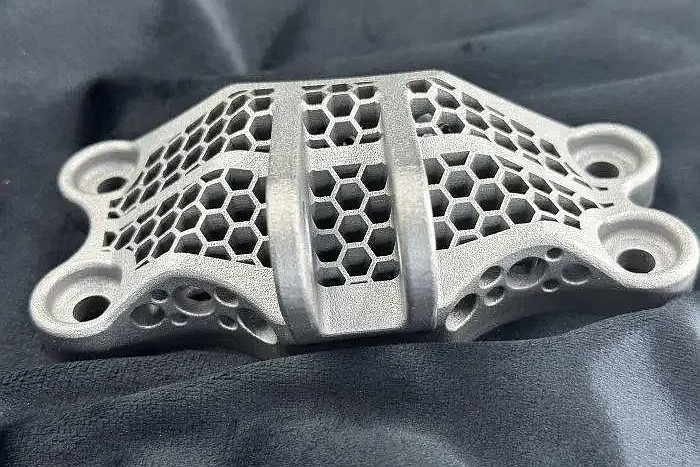

AlSi10Mg is one of the most widely used aluminum alloys for additive manufacturing, recognized for its lightweight structure, excellent castability, and robust mechanical properties following heat treatment. Its composition contains approximately 10% silicon and small amounts of magnesium, providing an exceptional strength-to-weight ratio and improved hardness compared with conventional aluminum alloys. When processed through aluminum 3D printing, AlSi10Mg exhibits fine microstructures, high dimensional accuracy, and stable performance, making it suitable for industrial-grade engineering applications. The alloy offers excellent thermal conductivity, corrosion resistance, and fatigue strength, making it ideal for aerospace brackets, heat exchangers, housing components, and automotive lightweight parts. With Neway’s advanced laser powder bed fusion capabilities, AlSi10Mg parts can achieve near-cast properties while enabling geometries that traditional casting or machining cannot produce.

International Naming Table

Region / Standard | Naming / Designation |

|---|---|

Europe (EN) | AlSi10Mg |

USA (ASTM) | A360 or similar Al-Si-Mg cast alloys |

Germany (DIN) | GX10 |

China (GB/T) | ZL101 equivalent family |

Japan (JIS) | AC4C similar grade |

Alternative Material Options

Several aluminum and lightweight alloys can be chosen as alternatives to AlSi10Mg depending on the required thermal, mechanical, and environmental performance. For higher strength and heat resistance, superalloy 3D printing may be preferred for demanding aerospace or power-generation environments. When improved corrosive-environment compatibility is required, aluminum-magnesium alloys or 6000/7000 series wrought aluminum can be considered. In 3D printing applications requiring greater ductility, high-performance aluminum materials such as Scalmalloy (Al-Mg-Sc) or AlSi7Mg offer enhanced elongation. For extreme strength-to-weight optimization, titanium materials such as Ti-6Al-4V (TC4) or aluminum composite powders may also be selected.

Design Intent of AlSi10Mg

AlSi10Mg was originally developed for precision casting applications requiring high fluidity, excellent mold filling characteristics, and low shrinkage. Its high silicon content enhances castability and reduces the likelihood of hot cracking, while magnesium provides age-hardening capabilities that increase strength and fatigue resistance. With the advancement of additive manufacturing, the alloy has become a natural fit for powder bed fusion processes due to its predictable melting behavior, low thermal expansion, and ability to form fine microstructures through rapid solidification. These characteristics make AlSi10Mg especially suitable for lightweight functional parts, heat-dissipating structures, conformal cooling channels, and components that benefit from optimized geometry or reduced mass. Its design intent in 3D printing is to achieve strong, reliable aluminum parts with enhanced fatigue life and high structural consistency.

Chemical Composition (wt%)

Element | wt% |

|---|---|

Si | 9.0–11.0 |

Mg | 0.25–0.45 |

Fe | ≤0.55 |

Cu | ≤0.05 |

Mn | ≤0.45 |

Zn | ≤0.10 |

Ti | ≤0.15 |

Others | ≤0.05 each |

Al | Balance |

Physical Properties

Property | Value |

|---|---|

Density | 2.67 g/cm³ |

Melting Range | 570–590 °C |

Thermal Conductivity | ~150 W/m·K |

Electrical Conductivity | Moderate |

Elastic Modulus | 70 GPa |

Coefficient of Thermal Expansion | 20–22×10⁻⁶ /K |

Mechanical Properties (AM + Heat Treated)

Property | Value |

|---|---|

Ultimate Tensile Strength | 420–480 MPa |

Yield Strength | 250–320 MPa |

Elongation | 6–12% |

Hardness | 110–130 HB |

Fatigue Strength | Good |

Density Reduction Efficiency | Excellent |

Material Characteristics

AlSi10Mg offers an optimal combination of low density, high surface quality, and competitive mechanical strength, making it a highly desirable alloy in additive manufacturing. Its low mass, combined with silicon-reinforced strength, enables engineers to develop lightweight parts without sacrificing durability. The alloy’s excellent thermal conductivity makes it ideal for heat exchangers, electronic housings, and high-efficiency cooling structures. Rapid solidification during 3D printing produces fine cellular microstructures that significantly improve strength and fatigue resistance compared to cast AlSi10Mg. The alloy also responds well to artificial aging, allowing further strength improvements through precipitation hardening. Corrosion resistance is strong in general atmospheric and marine environments due to its protective oxide layer. Its stable mechanical behavior under cyclic loading makes it suitable for aerospace and automotive fatigue-critical components. AlSi10Mg also exhibits good dimensional stability and low distortion during printing, making it an ideal material for precision mechanical parts, thin-wall geometries, and intricate topology-optimized structures.

Manufacturing Process Performance

AlSi10Mg is highly compatible with laser powder bed fusion due to its low melting temperature, excellent flowability, and predictable thermal behavior. It produces dense, high-quality components with minimal porosity, especially when processed under optimized printing conditions. Although primarily used for additive manufacturing, AlSi10Mg can also be fabricated using vacuum investment casting for near-net-shape components. The alloy performs well in this process thanks to its high fluidity and low hot-cracking tendency. Machining behavior is generally good, but attention must be paid to tool lubrication and chip clearance, as the alloy has a tendency to form a built-up edge. When finishing complex components, processes such as superalloy CNC machining may be applied to ensure dimensional accuracy. The alloy is compatible with drilling and thin-wall finishing, though high-speed tools are preferred. EDM can also be used when creating fine internal channels or sharp transitions. In additive manufacturing workflows, AlSi10Mg benefits significantly from heat treatment and surface finishing processes, ensuring stable performance and reliability across industrial applications.

Applicable Post-processing

Post-processing is crucial to unlocking the full mechanical potential of AlSi10Mg. Solution heat treatment followed by artificial aging increases hardness, tensile strength, and fatigue life. HIP via Hot Isostatic Pressing can eliminate porosity and further stabilize microstructures. Surface finishing methods such as shot peening, chemical polishing, anodizing, and machining improve surface quality and enhance corrosion resistance. For high-performance components, quality assurance through material testing and analysis ensures compliance with aerospace and industrial certification standards.

Common Applications

AlSi10Mg is widely used in the aerospace industry for lightweight brackets, housings, duct structures, and UAV components, where strength-to-weight optimization is crucial. Its excellent thermal conductivity also makes it a prime choice for heat exchangers, cooling plates, and electronic housings. In automotive engineering, AlSi10Mg is used for suspension components, structural supports, and lightweight performance parts. The alloy’s cast-like behavior and strong fatigue resistance make it a natural choice for industrial machinery, robotic arms, and equipment that require precision and durability. Beyond traditional industries, additive manufacturing is expanding its use into consumer electronics, tooling inserts with conformal cooling, and custom, lightweight mechanical assemblies.

When to Choose AlSi10Mg

Choose AlSi10Mg when lightweight performance, cost efficiency, and good mechanical properties are required. It is ideal for components where weight reduction directly impacts fuel efficiency, speed, or handling, such as aerospace brackets or automotive structures. This alloy is the ideal choice for designs requiring excellent thermal conductivity, making it suitable for use in heat exchangers and cooling modules. When producing topology-optimized or lattice structures, AlSi10Mg offers strong dimensional stability and consistent printability. AlSi10Mg is also suitable when corrosion resistance is required without the need for more expensive alloys. However, when extremely high strength, high-temperature capability, or superior fatigue performance is required, titanium or nickel-based superalloys may become more suitable.