Honeywell: Equiaxed Crystal Casting Secondary Turbine Vane Case Study

Introduction

In today’s aviation industry, with growing emphasis on fuel efficiency and lower emissions, the design and manufacturing of turbine components have never been more critical. Among these, the secondary turbine vane plays a vital role in shaping airflow downstream of the first-stage turbine blades, maintaining engine efficiency under extreme conditions. Honeywell, a renowned aerospace engine manufacturer, recently launched an advanced program to optimize the production of secondary turbine vanes using equiaxed crystal casting. This case study explores the engineering strategies, manufacturing processes, and quality controls involved in this project.

Honeywell Project Background and Design Requirements

Honeywell’s HTF7000 series engines, powering a range of business jets, demand secondary turbine vanes that can reliably operate in harsh environments. Positioned downstream of the first-stage blades, these vanes are exposed to temperatures ranging from 1100°C to 1150°C, along with fluctuating thermal and mechanical loads. Key design requirements included:

Excellent oxidation and corrosion resistance

High-low-cycle and high-cycle fatigue life

Precision aerodynamic profile and optimized internal cooling channels

Cost-effective production for commercial competitiveness

After extensive material evaluation, Honeywell engineers selected alloys such as Inconel 738 and Rene 77, both known for their robust high-temperature performance. The decision to use Superalloy Equiaxed Crystal Casting was driven by a combination of mechanical performance needs and cost optimization. Unlike single-crystal or directionally solidified blades, secondary vanes can tolerate grain boundaries when properly controlled, making equiaxed casting a pragmatic choice.

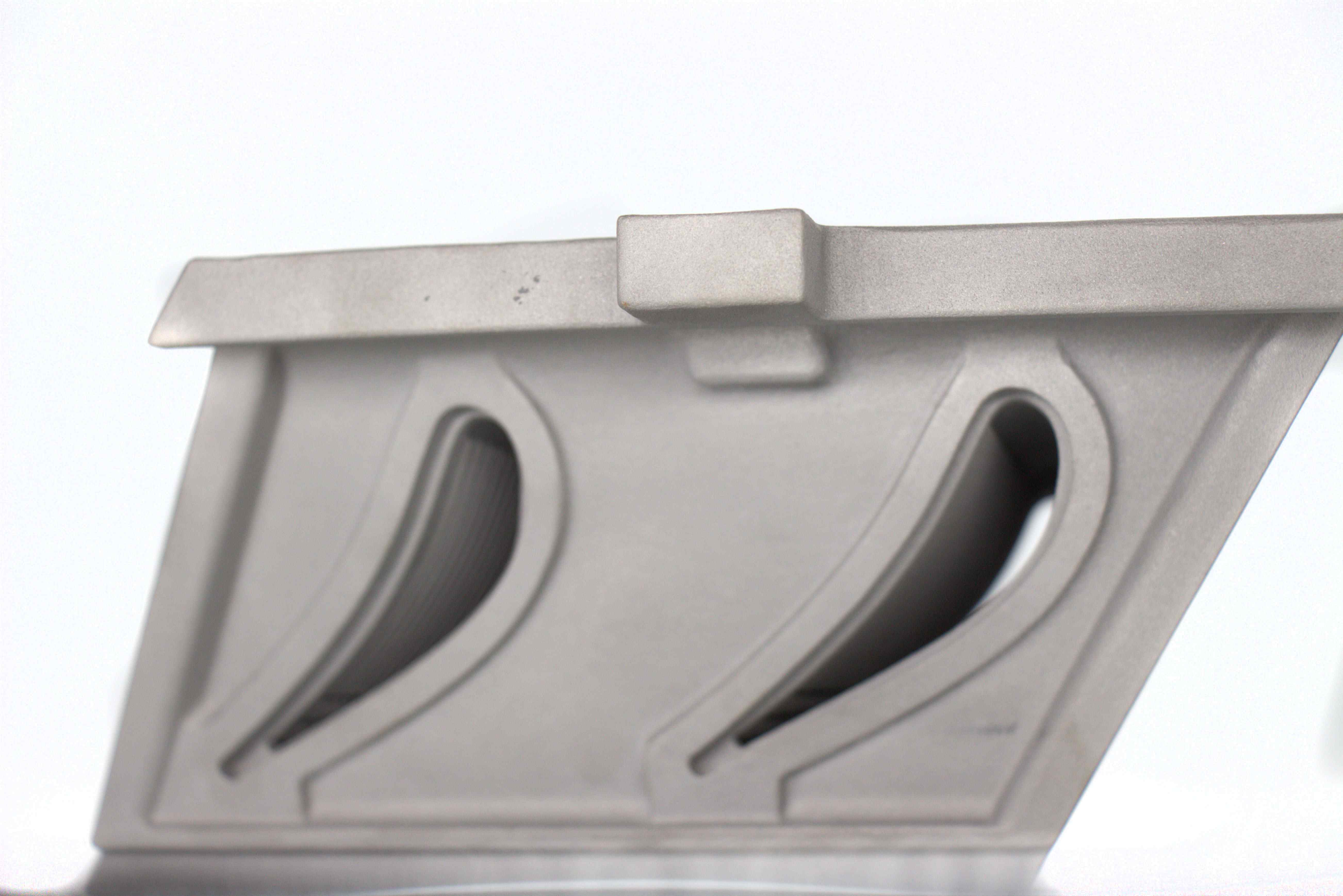

Equiaxed Crystal Casting Process Design

Process Design Logic

The choice of equiaxed casting offers several benefits:

Enhanced toughness due to a multi-grain structure

Reduced manufacturing cost compared to single-crystal casting

Greater flexibility in geometry, especially for complex vane cooling features

Given these factors, the Honeywell team tailored the process to achieve optimal microstructural control, focusing on grain size uniformity and minimal segregation.

Vacuum Melting and Ceramic Shell Preparation

At the core of the manufacturing process lies advanced Vacuum Investment Casting. The workflow begins with vacuum melting of the selected superalloy ingots to ensure high chemical purity. The ceramic mold preparation utilizes optimized Y2O3 + Al2O3 composite shell systems to withstand repeated thermal cycles and aggressive molten metal chemistry.

Key process parameters include:

Alloy melting temperature: 1600–1650°C

Mold preheating temperature: 1450–1500°C

Controlled pour rate to minimize turbulence and entrapped gas

Cooling rate tailored to grain structure objectives

The casting design also incorporates proprietary gating and riser configurations to promote directional solidification within the equiaxed regime.

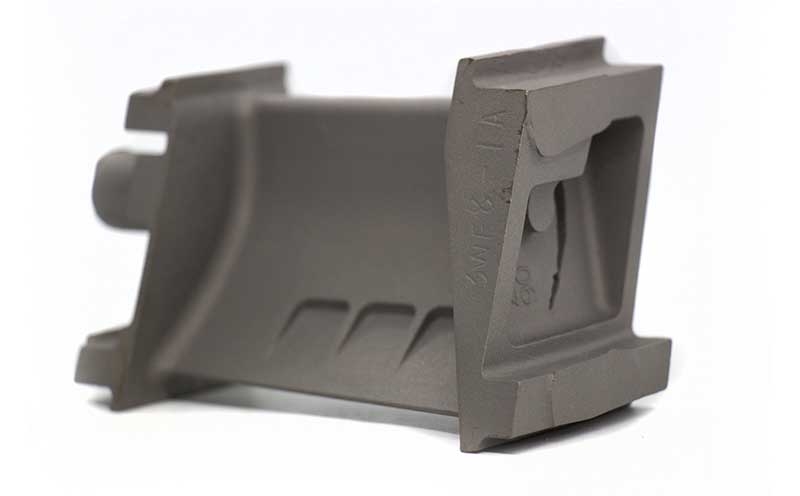

Defect Control and Inspection Processes

Typical Defect Types

Defect control is paramount in ensuring the mechanical integrity of secondary turbine vanes. Key defects targeted for elimination include:

Shrinkage porosity

Non-metallic inclusions

Coarse or non-uniform grain structure

Surface oxidation and ceramic inclusions

Inspection Techniques

Honeywell adopted a multi-stage inspection protocol using advanced nondestructive testing (NDT) and metallography:

Inspection Method | Target Defect | Equipment Example | Acceptance Criteria |

|---|---|---|---|

Porosity, shrinkage cavities | Industrial X-ray system | per AMS STD | |

Trace element impurities | GDMS spectrometer | < 0.01% impurity | |

Metallographic microscopy | Grain size and segregation | Optical microscope | ASTM E112 compliant |

CT scanning | Internal cooling channel integrity | Industrial CT scanner | Design specification conformance |

SEM + EDS | Surface inclusions and oxide layers | High-resolution SEM | No foreign phases permitted |

This robust inspection regime ensures that every vane meets stringent Honeywell and aerospace industry standards.

Post-Processing Techniques

Hot Isostatic Pressing (HIP)

Following casting, components undergo Hot Isostatic Pressing (HIP) to eliminate micro-porosity and homogenize the internal microstructure. Process conditions are precisely controlled:

Temperature: 1180–1220°C

Pressure: 100–150 MPa

Hold time: 3–4 hours

HIP significantly enhances fatigue performance, particularly important given the cyclic loading conditions experienced by secondary vanes.

Heat Treatment

Subsequent Heat Treatment further refines the alloy microstructure:

Solution treatment at 1190–1210°C to dissolve undesirable phases

Controlled cooling to tailor γ/γ' morphology

Aging treatments at 850–900°C to optimize high-temperature strength and fatigue resistance

These steps are critical for achieving the target creep and oxidation resistance performance metrics.

Surface Treatment: TBC and Surface Conditioning

Beyond the core metallurgical properties, surface protection is essential for secondary turbine vanes due to prolonged exposure to hot gas streams and corrosive environments. Honeywell employs advanced Thermal Barrier Coating (TBC) systems to provide this protection.

The TBC system consists of:

Bond coat: typically MCrAlY, providing oxidation resistance and a diffusion barrier

Ceramic topcoat: yttria-stabilized zirconia (YSZ), 100–250 µm thick, applied by air plasma spray or electron-beam physical vapor deposition (EB-PVD)

These coatings effectively reduce the metal surface temperature by 100–150°C, significantly extending vane life.

In addition, vanes undergo precision surface conditioning:

Removal of ceramic residues from internal and external surfaces

Polishing to achieve a surface roughness of Ra < 1.5 µm where required

Application of anti-oxidation coatings in select areas to prevent hot corrosion

This comprehensive approach ensures optimal performance and reliability in service.

Final Inspection and Qualification

Honeywell’s quality assurance process integrates rigorous inspection and qualification steps to ensure compliance with both internal and industry standards.

Mechanical Testing

Each production batch is subjected to:

Tensile Testing at room and elevated temperatures

Creep testing to validate long-term high-temperature strength

Fatigue testing under both low-cycle and high-cycle loading conditions

Non-Destructive Evaluation (NDE)

Advanced NDE techniques ensure component integrity:

100% X-ray Inspection for internal porosity and shrinkage

Industrial CT scanning to validate cooling passage geometry and detect potential defects

Eddy current inspection to confirm surface integrity

Final visual inspection by experienced technicians

Certification

Vanes are certified to comply with:

Honeywell's internal quality standards

SAE Aerospace Material Specifications (AMS)

ASTM and ISO standards for aerospace castings

Only components passing all inspections are released for engine assembly.

Honeywell Application Results

The newly optimized equiaxed crystal secondary turbine vanes have already been integrated into several of Honeywell’s engine platforms, including the HTF7000 and TPE331 series. The manufacturing team achieved impressive results:

15–20% reduction in production cost compared to previous methods

10–15% increase in component life due to enhanced microstructural control and surface protection

Improved consistency in aerodynamic profile and cooling channel accuracy

These gains contribute directly to engine efficiency, reduced maintenance costs, and enhanced customer satisfaction.

Field performance data from operational engines has validated the manufacturing improvements, with vane life exceeding projected service intervals and maintaining excellent reliability in harsh operating environments.

Industry Trends and Future Outlook

Looking ahead, the equiaxed crystal casting process is poised to evolve in several exciting ways.

Smart Manufacturing

Integration of digital twin models and AI-driven process monitoring promises to further refine casting quality and yield.

Hybrid Manufacturing

Combining equiaxed casting with precision Superalloy CNC Machining and Superalloy 3D Printing enables more complex vane geometries and performance-optimized designs.

Advanced Materials

Research into new alloy compositions and next-generation TBC systems will push component performance even further, supporting hotter and more efficient engines.

For engineers like me, it is an exciting time to be at the forefront of such innovations, helping shape the future of aerospace propulsion through material and manufacturing excellence.

Summary and Engineer’s Reflection

The Honeywell secondary turbine vane project exemplifies the powerful synergy of traditional craftsmanship and cutting-edge technology. Through careful process design, meticulous quality control, and innovative post-processing, the team delivered a component that meets today’s demanding engine requirements while maintaining commercial competitiveness.

As we look toward the future, the ongoing evolution of casting technologies and materials science will continue to open new possibilities. For now, these equiaxed crystal vanes stand as a testament to what can be achieved through thoughtful engineering and unwavering attention to detail.

FAQs

What are the advantages of equiaxed crystal casting for turbine vanes?

Why did Honeywell choose equiaxed casting for secondary turbine vanes?

How does TBC improve the performance of secondary turbine vanes?

What inspection methods ensure vane quality in aerospace applications?

What alloys are commonly used in equiaxed cast secondary turbine vanes?