CMSX Series Turbine Blades Precision Forging Foundry

Introduction to CMSX Turbine Blade Forging

The CMSX (Cobalt–Molybdenum–Superalloy Experimental) series represents a family of high-performance single crystal superalloys developed for turbine blades in next-generation aerospace and industrial gas turbines. Neway AeroTech is a specialized precision forging foundry with advanced capabilities in manufacturing CMSX series turbine blades, including CMSX-4, CMSX-10, and CMSX-486.

Our precision forging processes enable high structural integrity, consistent grain orientation, and dimensional accuracy for critical rotating and static turbine airfoils.

Why Choose Forging for CMSX Turbine Blades?

While CMSX alloys are typically associated with casting, forged CMSX components offer benefits in specific applications where directional strength and superior surface integrity are essential:

Enhanced Grain Control: Isothermal or hot-die forging aligns grains for improved creep and fatigue resistance.

Superior Surface Quality: Forged surfaces are less porous and have reduced casting defects.

High Dimensional Precision: Forging minimizes material waste and improves tolerance consistency.

Structural Integrity: Forged blades demonstrate better resistance to thermal shock and crack propagation.

Core Challenges in Forging CMSX Alloys

Challenge | Solution |

|---|---|

Narrow forging temperature window (~1100–1180°C) | Advanced temperature-controlled forging dies and thermal simulation |

Strain rate sensitivity | Controlled forging speeds and isothermal press systems |

Oxidation sensitivity | Inert gas or vacuum forging environments |

Crystallographic orientation | Pre-oriented billet prep or seeded forging for directional integrity |

CMSX Series Alloys for Forged Turbine Blades

Alloy | Creep Strength | Max Operating Temp | Typical Grain Type | Common Application |

|---|---|---|---|---|

Excellent | 1150°C | Single Crystal (SC) | Jet engine HPT blades, IGT airfoils | |

Superior | 1175°C | SC | Military engine airfoils | |

CMSX-486 | Excellent | 1130°C | SC / DS | Turbine blades for power turbines |

Very Good | 1080°C | SC | Compressor exit vanes, hot section | |

Good | 1065°C | Directional | IGT first-stage blades |

Precision Forging Process Flow for CMSX Blades

Alloy Ingot Preparation

High-purity CMSX alloy prepared via vacuum arc melting.

Orientation-controlled billets pre-machined for forging.

Die Design and Simulation

Custom die sets engineered for blade profile and cooling features.

FEM simulation used to predict strain, grain flow, and defect risks.

Hot / Isothermal Forging

Forging performed at 1100–1180°C using precision dies.

Inert or vacuum environment minimizes oxidation.

Post-Forging Treatment

Hot Isostatic Pressing (HIP) to eliminate residual porosity.

Heat treatment to optimize gamma/gamma prime microstructure.

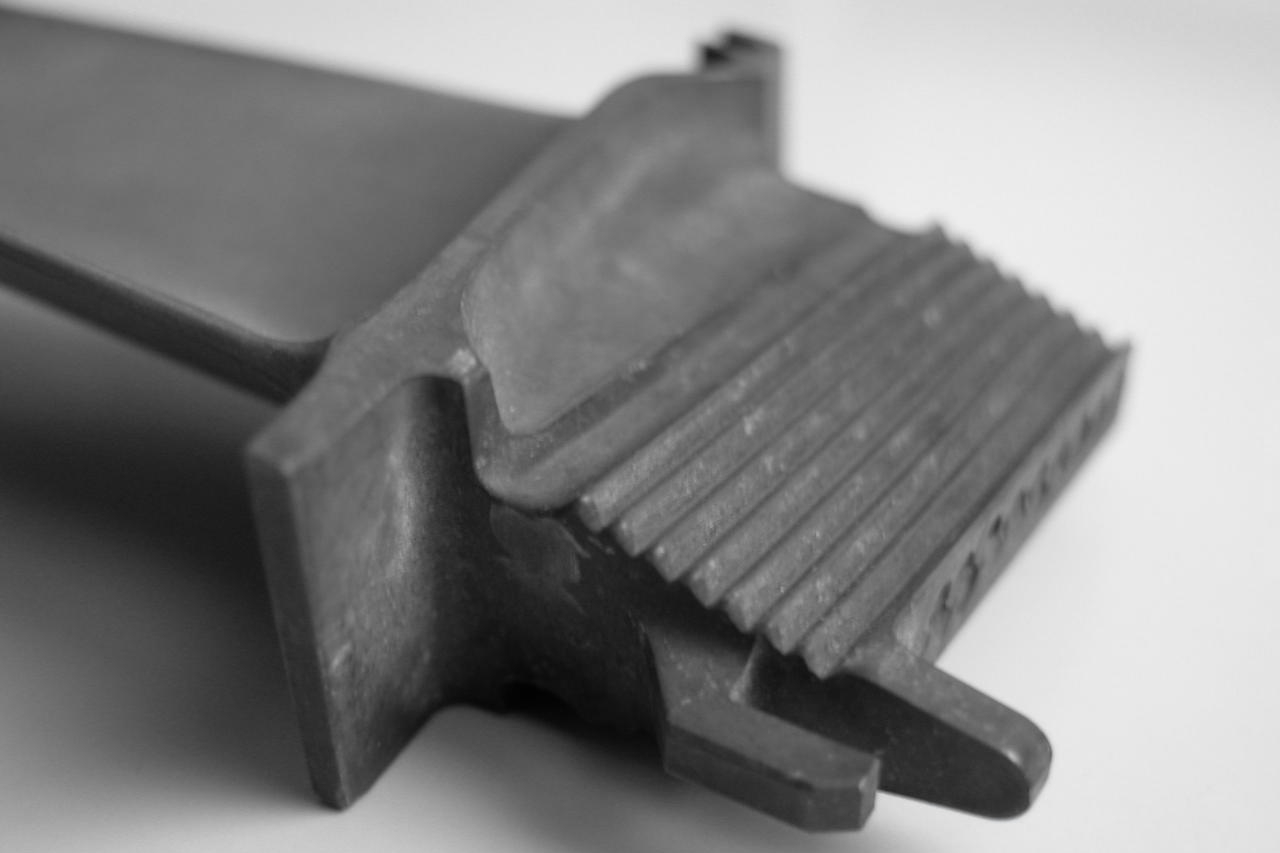

CNC Machining for root profiles, tips, and platform surfaces.

Inspection and Testing

Non-destructive Testing (NDT) includes ultrasonic, X-ray, and EBSD grain orientation validation.

Dimensional inspection to ±0.01 mm precision.

Forging vs. Casting for CMSX Blades

Feature | Forging (CMSX) | Vacuum Investment Casting (CMSX) |

|---|---|---|

Grain Orientation | Directional / Controlled | Directional / Single Crystal |

Surface Quality | Superior | Good with secondary processing |

Internal Porosity | Minimal (with HIP) | May require HIP |

Design Flexibility | Moderate | High |

Production Cost | Higher (small batches) | Lower for large volumes |

Mechanical Strength | Excellent | Excellent |

Case Study: CMSX-4 Forged Blades for Aero Engine Program

Neway AeroTech partnered with an aerospace OEM to produce CMSX-4 forged turbine blades for a military-grade high-pressure turbine. Using orientation-controlled forging, HIP, and a multi-step heat treatment cycle, we achieved dimensional accuracy within ±0.01 mm and confirmed grain alignment via EBSD. The forged blades demonstrated over 1100°C creep resistance and improved cyclic durability over cast equivalents.

FAQs

Do you offer isothermal forging for CMSX turbine blades?

What is the maximum forging size for CMSX airfoils?

Can you assist with die design and material simulation?

What post-processing treatments do you offer for forged CMSX blades?

How do you verify grain orientation and internal quality after forging?