What is the role of precision forging in manufacturing heat exchanger parts?

Optimized Grain Structure for Thermal Cycling

Precision forging plays a pivotal role in manufacturing high-performance heat exchanger parts by creating a continuous, directional grain flow that aligns with the component's geometry. This refined and uniform microstructure, achieved through processes like superalloy precision forging, significantly enhances resistance to thermal fatigue and creep deformation. For parts such as tube sheets, headers, and U-bends that undergo constant thermal cycling, this forged integrity prevents the initiation and propagation of cracks, ensuring long-term operational reliability in demanding power generation and chemical processing applications.

Enhanced Corrosion Resistance and Material Density

The forging process consolidates the material, eliminating the internal porosity and micro-shrinkage that are common in cast components. This results in a homogenous, high-density structure with superior resistance to corrosive media. For heat exchangers handling aggressive chemicals or seawater, using forged Inconel 625 or Hastelloy C-276 parts drastically reduces the risk of pitting and stress corrosion cracking, which are critical failure modes. This dense microstructure is often further enhanced with Hot Isostatic Pressing (HIP) to guarantee maximum integrity.

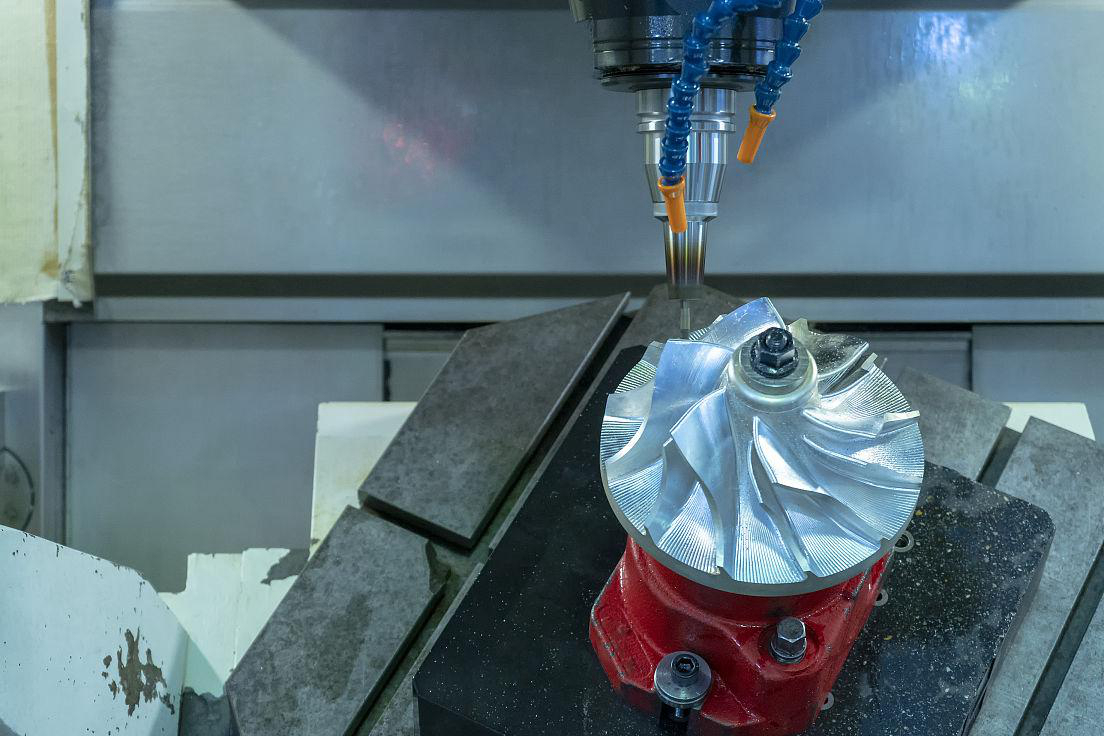

Near-Net-Shape Efficiency for Complex Geometries

Precision forging is a near-net-shape process, which is highly advantageous for expensive high-performance alloys. It minimizes material waste and significantly reduces the amount of subsequent machining required. This is crucial for creating complex features integral to heat exchangers, such as extended surfaces or manifold passages, with a minimal buy-to-fly ratio. The forged preform requires only final precision machining via superalloy CNC machining to achieve tight tolerances on sealing surfaces and bolt holes, streamlining the entire manufacturing workflow.

Superior Mechanical Properties at Elevated Temperatures

Forged components exhibit higher strength and toughness compared to their cast or fabricated counterparts, properties that are retained at the elevated operating temperatures of modern heat exchangers. This ensures structural integrity under high pressure loads and prevents deformation. The consistent material properties achieved through forging, followed by precise heat treatment, provide a predictable and reliable performance baseline, which is essential for the safety and efficiency of critical industrial systems.