What is the role of precision forging in firearm accessory manufacturing?

Precision Forging for Firearm Performance

Precision forging plays a crucial role in manufacturing firearm accessories that demand high strength-to-weight ratios, dimensional stability, and resistance to cyclic firing stresses. Unlike traditional machining from billet stock, forging enhances grain flow alignment and eliminates internal defects through controlled deformation. This results in superior fatigue performance and greater durability—essential for components such as charging handles, bolt carriers, gas blocks, and trigger housings. When combined with high-performance superalloys like Inconel 625 and alloyed titanium options, forging improves firearm accessory strength without increasing mass.

Advanced techniques, such as superalloy precision forging, allow for precise control of grain direction, forming temperature, and deformation rate. This ensures structural consistency under rapid mechanical stress and thermal shock during continuous firing. The forged microstructure has higher resistance to crack propagation than cast or fully machined parts, making it ideal for high-impact zones in military and tactical applications.

Forging Process and Structural Advantages

During forging, the material’s internal grain structure is compressed and aligned along the stress path, resulting in significant improvements in fatigue strength and toughness. The process also reduces porosity and inclusions, making the components more reliable under gas expansion loads and recoil forces. For enhanced microstructural control, forging can be followed by precision-controlled heat treatment to further refine hardness and stabilize alloy phases.

Complex geometries—such as lightweight handguards or reinforced mounting interfaces—can be formed using closed-die forging, ensuring consistency across large-scale production series. When manufacturing higher-performance firearm platforms, combining forging with real-time inspection and material testing and analysis ensures traceability and reliability under extreme service conditions.

Integration with Modern Manufacturing

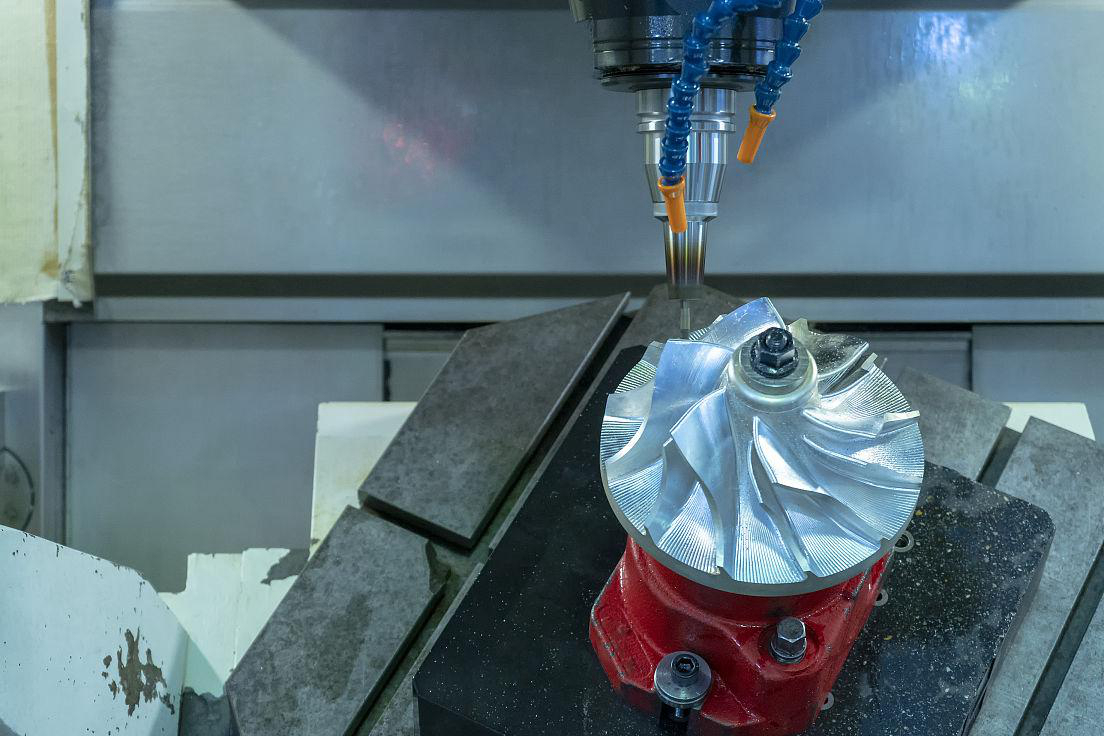

Forged blanks are typically finished through precision machining to achieve tight tolerances and final functional features. Multi-axis CNC machining is commonly used for final shaping, while surface condition and stress distribution are optimized via post-processes like hot isostatic pressing (HIP) and surface treatments such as thermal barrier coating (TBC) for heat and wear protection.

As firearm technology evolves toward higher-cycle endurance and lightweight modular design, precision forging offers a crucial balance of mass efficiency, structural integrity, and repeatability in high-volume production. Its versatility supports both commercial and defense-grade firearm systems, enabling long-term reliability across diverse operating environments.