What are the advantages of isothermal forging for superalloy furnace parts?

Improved Microstructural Control

Isothermal forging allows superalloy furnace components to be formed at temperatures close to their recrystallization range, promoting uniform grain growth and excellent phase stability. Alloys such as Rene 104 and Nimonic 115 benefit significantly from this process, achieving superior creep resistance and oxidation stability—vital for furnace liners, baffles, and burner assembly parts exposed to extreme temperatures.

Complex Geometry and Formability

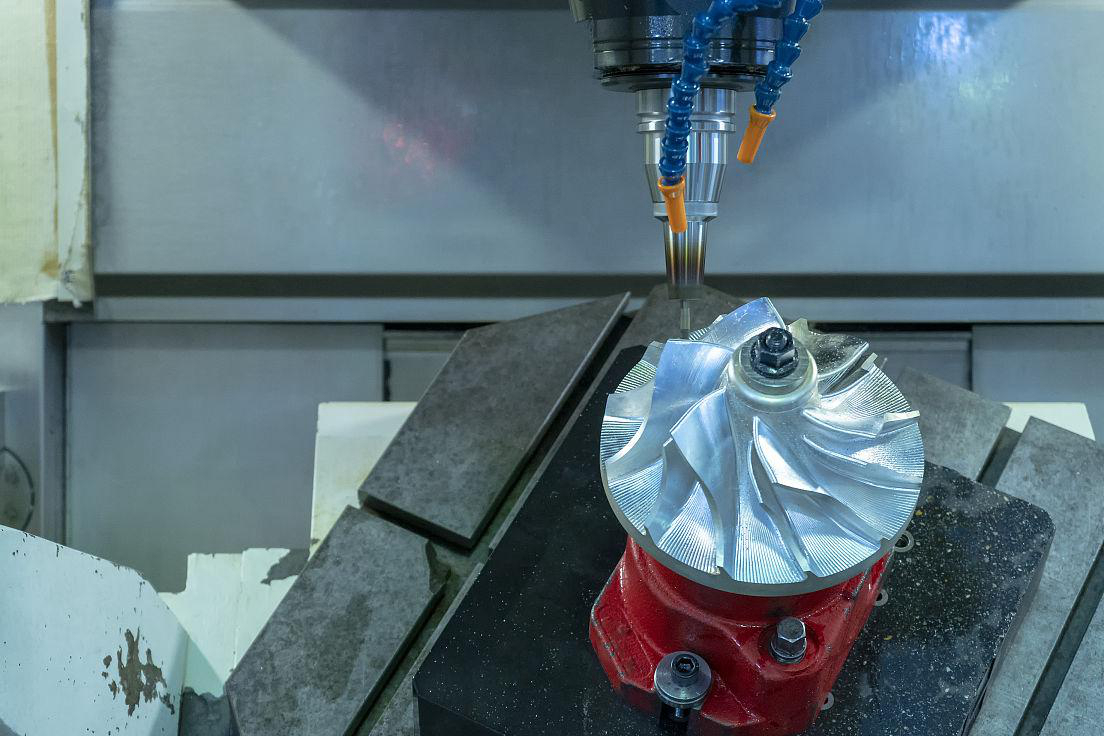

Furnace modules often include thin sections or intricate features that conventional forging struggles to achieve. Isothermal forging reduces flow stress and increases formability, enabling precise shaping of complex geometries with fewer defects. Critical surfaces requiring high precision can be subsequently finished using superalloy CNC machining, maintaining dimensional accuracy and consistent heat flow performance.

Defect Reduction and Fatigue Resistance

The controlled temperature environment prevents strain hardening and microcrack initiation, resulting in higher component reliability. When paired with post-processing techniques such as hot isostatic pressing (HIP) or superalloy heat treatment, isothermally forged parts demonstrate significantly improved fatigue life—ideal for furnace environments with repeated thermal cycling.

Industrial Applications and Performance

This forging method is especially valuable for components used in high-demand sectors such as chemical processing, power generation, and offshore marine systems. Enhanced structural integrity and process traceability allow engineers to predict component lifecycles more accurately and minimize maintenance downtime in critical furnace assemblies.