How does isothermal forging improve distillation component manufacturing?

Enhanced Microstructural Refinement

Isothermal forging allows superalloy distillation components to be deformed at temperatures near the alloy’s recrystallization point, enabling controlled grain refinement and excellent phase stability. Alloys such as Rene 65 and Nimonic 901 benefit significantly from this process, achieving superior tensile properties, better thermal stability, and greater resistance to creep and corrosion—all essential for distillation trays, baffles, and pressure-resistant housings.

Improved Forming of Complex Geometries

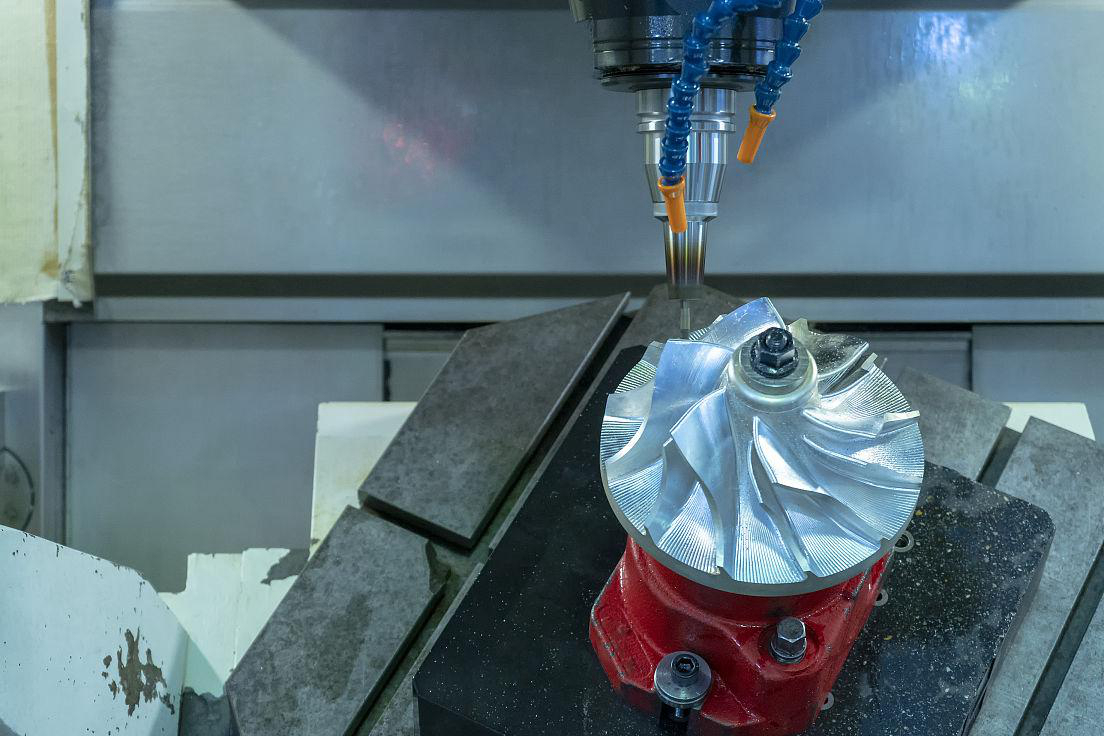

Distillation modules often require thin-walled designs and complex internal structures to optimize vapor-liquid interaction. Unlike conventional forging, isothermal forging minimizes tool stresses and deformation resistance, allowing more precise shaping of intricate geometry. When combined with advanced machining such as superalloy CNC machining, the process achieves tight dimensional tolerances with fewer defects and reduced post-processing requirements.

Defect Reduction and Material Efficiency

The uniform temperature environment of isothermal forging prevents microcrack formation and avoids excessive strain hardening. This results in fewer inclusions and improved anisotropy control compared to traditional forging. For strength-critical parts, isothermal forging may be followed by superalloy heat treatment or hot isostatic pressing (HIP) to further strengthen the component and optimize its lifecycle performance under continuous chemical exposure.

Reliability in Industrial Conditions

Isothermal forging is particularly valuable for components used in harsh process environments such as chemical processing and oil and gas. The process enhances structural uniformity, resulting in improved fatigue resistance and an extended operational lifespan. With proper material testing and analysis, forged superalloy components provide stable performance under pressure cycling and corrosive fluid flow—ensuring reliable long-term operation within distillation columns.