Superalloy Deep Hole Drilling Parts Micro Hole CNC Processing

High-Precision Drilling for Critical Applications

Micro-hole and deep-hole drilling in superalloys is essential for components exposed to high heat, pressure, and cyclic stress. In 2024, demand surged for precision-drilled cooling channels in jet engines, power turbines, and chemical reactors—requiring CNC tolerances below 10 μm and hole depths exceeding 20×D.

Neway AeroTech delivers advanced superalloy CNC machining and deep hole drilling services for aerospace-grade alloys like Inconel 718, CMSX-4, and Rene 88 for critical gas and fluid flow components.

Core Technology of Micro Hole CNC Processing

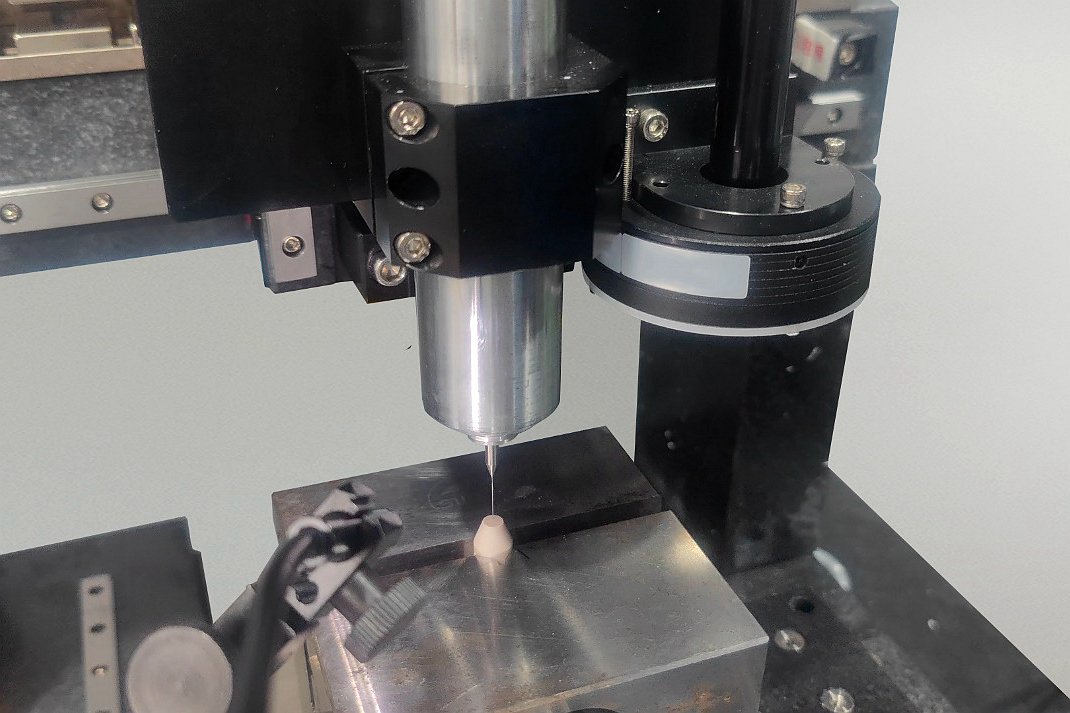

Neway AeroTech utilizes high-rigidity 5-axis CNC centers and EDM for producing micro holes in tough superalloys.

Deep hole drilling up to 25×D with coolant-fed carbide drills.

Micro EDM for sub-0.3 mm holes and heat-resistant features.

Orbital drilling and peck cycles reduce burrs and improve wall straightness.

In-process probing ensures position accuracy within ±5 μm across angled bores.

All processes meet NADCAP and AS9100D standards for flight-critical parts and turbine systems.

Typical Superalloy Materials for Micro Hole Processing

Alloy | Max Temp (°C) | Yield Strength (MPa) | Applications |

|---|---|---|---|

704 | 1035 | Fuel nozzles, cooling channels | |

1140 | 980 | Turbine blades, impingement holes | |

980 | 1250 | Engine casing vents | |

920 | 1265 | Nozzle guide vane cooling ports |

Alloys are chosen for oxidation resistance, strength retention, and machinability under thermal gradients.

Case Study: Micro Cooling Holes for Turbine Vane Segment

Project Background

A turbine manufacturer required sub-0.6 mm cooling holes machined at compound angles through a 5 mm thick CMSX-4 segment. Tolerance was ±0.01 mm with no thermal distortion or taper. Deep-hole drills and EDM were used in tandem to achieve required geometry and metallurgical quality.

Typical Drilled Component Models and Applications

Part Model | Description | Material | Hole Depth | Industry |

|---|---|---|---|---|

VN-300 | Vane with 18 micro impingement holes, angled 30°–60° | CMSX-4 | 8×D | |

TN-120 | Turbine nozzle insert with 0.4 mm film holes | Rene 88 | 6×D | |

EIH-200 | Heat exchanger header with parallel bore arrays | Inconel 718 | 15×D | |

PCH-480 | Pressurized housing with radial vent holes | Nimonic 90 | 10×D |

Hole precision and angle entry were critical for downstream fluid flow and fatigue resistance.

CNC Challenges in Superalloy Deep Hole Drilling

Tool deflection beyond 0.03 mm due to aspect ratios exceeding 10×D.

Thermal softening at >600°C in poor-conductivity CMSX leads to dimensional instability.

Micro cracks during EDM require optimized pulse control to avoid recast layer >2 μm.

Bore deviation over long holes caused by chip congestion without high-pressure flushing (>80 bar).

Angle drilling at >45° requires 5-axis compensation and multi-stage entry drilling.

CNC Solutions for Deep and Micro Hole Machining

High-pressure coolant at 100 bar used for chip evacuation in Inconel 718 bores >12×D.

Orbital pre-holes with EDM finishing achieved 0.3 mm diameter with <2 μm roundness deviation.

Peck drilling cycles with torque monitoring reduced tool breakage by 40%.

Workholding with 5-face clamping ensured angular bore deviation within ±0.005 mm.

Post-EDM cleaning and passivation eliminated recast layer contamination.

Results and Verification

Manufacturing Methods

Components were machined using vacuum investment casting blanks and refined using 5-axis CNC machining and deep hole drilling systems. Multi-axis drilling ensured radial entry control across variable contours and complex wall geometries.

Precision Finishing

Microbores were refined to Ra ≤ 0.4 μm using EDM and reaming cycles. Deep hole drilling systems with <0.01 mm TIR ensured roundness, while multi-stage pilot drilling and coolant-fed carbide tooling supported bore depths up to 20×D.

Post-Processing

HIP removed internal porosity, followed by stress relief heat treatment at 870–980°C. Surface passivation and optional coating application ensured long-term corrosion and thermal resistance.

Inspection

CMM validated bore straightness within ±0.006 mm; SEM examined entry lip integrity; and X-ray confirmed alignment in hidden features. All parts passed helium leak and high-cycle fatigue validation per customer specs.

FAQs

What is the minimum diameter achievable with superalloy deep hole drilling?

How do you maintain bore straightness in long holes?

Can you combine EDM and drilling in one process?

What materials are best for micro-hole coolant channels?

What testing is required to validate thermal hole performance?