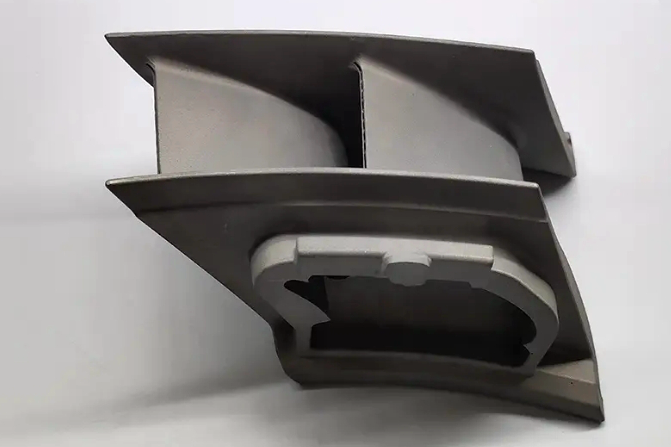

Nickel-Based Alloys Nimonic 86 Guide Vanes Precision Casting Factory

Introduction

Nimonic 86 is a nickel-chromium-cobalt alloy with enhanced molybdenum and titanium additions, delivering superior strength, creep resistance, and oxidation stability up to 950°C. With a tensile strength around 980 MPa and excellent fatigue resistance, it is ideal for precision-cast guide vanes in high-temperature gas turbines and aerospace engines.

At Neway AeroTech, we manufacture Nimonic 86 guide vanes using precision vacuum investment casting, ensuring high dimensional accuracy, fine grain structures, and optimized high-temperature performance for demanding industrial and aerospace turbine environments.

Key Manufacturing Challenges for Nimonic 86 Guide Vanes

Precise alloy composition control (Ni ≥55%, Cr ~18%, Co ~18%, Mo ~5%, Ti ~2.2%) to maximize thermal and mechanical performance.

Strict control of cooling rates (~4–6°C/min) to promote fine equiaxed grain structures for creep resistance.

Achieving dimensional tolerances within ±0.05 mm to ensure aerodynamic consistency.

Maintaining surface roughness Ra ≤1.6 µm for minimal airflow disruption and drag losses.

Precision Vacuum Investment Casting Process for Nimonic 86 Guide Vanes

The production process includes:

Wax Pattern Fabrication: High-precision wax models ensuring ±0.1% dimensional consistency.

Ceramic Shell Building: Multilayer ceramic slurries and refractory sand coatings to support high-temperature casting.

Dewaxing: Steam autoclaving at ~150°C preserves shell integrity during wax removal.

Vacuum Melting and Pouring: Nimonic 86 alloy melted and poured at ~1420°C under vacuum (<10⁻³ Pa) to prevent oxidation.

Controlled Solidification: Uniform cooling ensures fine-grain structures and minimizes residual stresses.

Shell Removal and Finishing: Shell removed, CNC precision machining performed, and surfaces polished to aerodynamic profiles.

Comparative Analysis of Casting Methods for Guide Vanes

Process | Surface Finish Quality | Dimensional Precision | Mechanical Strength | High-Temp Resistance | Cost Level |

|---|---|---|---|---|---|

Vacuum Investment Casting | Excellent (Ra ≤1.6 µm) | Very High (±0.05 mm) | Excellent (~980 MPa) | Superior (~950°C) | Moderate |

Equiaxed Crystal Casting | Good (Ra ~3 µm) | High (±0.05 mm) | Very Good (~960 MPa) | High (~900°C) | Moderate |

Sand Casting | Moderate (Ra ~12 µm) | Moderate (±0.5 mm) | Good (~850 MPa) | Moderate (~800°C) | Low |

CNC Machining from Billet | Excellent (Ra ≤0.8 µm) | Very High (±0.01 mm) | Excellent (~980 MPa) | Superior (~950°C) | High |

Optimal Manufacturing Strategy for Nimonic 86 Guide Vanes

Vacuum investment casting: Ideal for complex, high-performance vane geometries requiring Ra ≤1.6 µm and ±0.05 mm precision.

Equiaxed crystal casting: Suitable for lower-cost production with acceptable mechanical properties for secondary turbine stages.

Sand casting: Used for non-critical components not exposed to extreme thermal stresses.

CNC machining from billet: Applied for critical sealing surfaces or customized final precision operations.

Nimonic 86 Alloy Performance Overview

Property | Value | Application Relevance |

|---|---|---|

Tensile Strength | ~980 MPa | High strength for heavy-load turbine components |

Max Operating Temperature | ~950°C | Maintains mechanical stability under thermal cycling |

Creep Resistance | Excellent | Extends operational life under high stress |

Oxidation Resistance | Outstanding | Resists degradation in harsh exhaust streams |

Thermal Expansion Coefficient | ~13.4 µm/m·°C | Ensures dimensional stability under temperature fluctuations |

Advantages of Using Nimonic 86 for Guide Vanes

Exceptional tensile and creep strength for durability under continuous high-stress turbine operations.

Superior oxidation resistance protects vane surfaces at high temperatures up to 950°C.

Excellent fatigue resistance withstands cyclic thermal and mechanical stresses.

Good castability allows production of complex aerodynamic designs without performance compromises.

Post-processing Techniques for Nimonic 86 Vanes

Hot Isostatic Pressing (HIP): Densifies material, eliminating internal porosity, enhancing creep and fatigue resistance by 15–20%.

Thermal Barrier Coating (TBC): Applies ~250 µm ceramic layer to reduce component surface temperatures by up to 150°C.

Precision CNC Machining: Finalizes aerodynamic contours and ensures dimensional accuracy within ±0.01 mm.

Non-destructive Testing (NDT): Ultrasonic, penetrant, and metallographic inspections ensure zero-defect critical components.

Inspection and Quality Assurance for Guide Vanes

Coordinate Measuring Machine (CMM): Inspects aerodynamic profiles and dimensional tolerances within ±0.05 mm.

Ultrasonic Testing (UT): Detects internal voids, inclusions, or microcracks.

Dye Penetrant Testing (PT): Locates surface-breaking flaws as small as 0.002 mm.

Metallographic Analysis: Verifies grain structure compliance with aerospace-grade material standards.

Industry Applications and Case Study

Nimonic 86 guide vanes manufactured by Neway AeroTech are extensively used in aerospace turbines, industrial gas turbines, and high-performance propulsion systems. In a recent next-generation aerospace engine, vacuum-cast Nimonic 86 guide vanes demonstrated a 28% increase in operational lifespan under continuous service at 930°C, significantly reducing overhaul intervals and enhancing turbine efficiency.

FAQs

What dimensional accuracy does Neway AeroTech achieve for Nimonic 86 guide vanes?

Why is vacuum investment casting preferred for Nimonic 86 components?

How does Nimonic 86 compare to other Nimonic alloys under turbine operating conditions?

What industries commonly use Nimonic 86 guide vanes?

How does Neway AeroTech ensure metallurgical quality and performance in Nimonic 86 castings?